The Bending of copper tubes

The water supply pipes have a diameter ranging from 10 to 22 mm. A diameter of 10 mm matches with 1 mm of pipe thickness, so inside diameter is 8 mm (10-2).

Important : there are two types of copper in plumbing.

The so-called «hard» copper is a rigid metal which must not be cold bent. It usually appears in the form of long straight bars from 1 to 5 meters. It has a hard, dry appearance and warps less than annealed copper (not easy to scratch). It is mainly used in visible installations, fixed with wall clamps, single or double, oftenly soundproof.

How does "hard" copper look:

On the other hand, “annealed” copper or crown copper can be worked simply. It is generally presented as crowns of 2 to 50 meters. To recognize it, note its greasy appearance and can be easily scratched. The copper has undergone after its work hardening a heating making it malleability.

How does "annealed" copper look:

An annealed tube implies a slightly lower mechanical resistance but more simple to work because of its malleability linked to its elongation. Sheathed in a sheath, these tubes can also be integrated into a screed.

Using the pipe bending tool and bending spring

1- The bending tool :

The advent of semi-hard tubes brought about an important change in bending techniques as they were specially designed to facilitate cold forming.

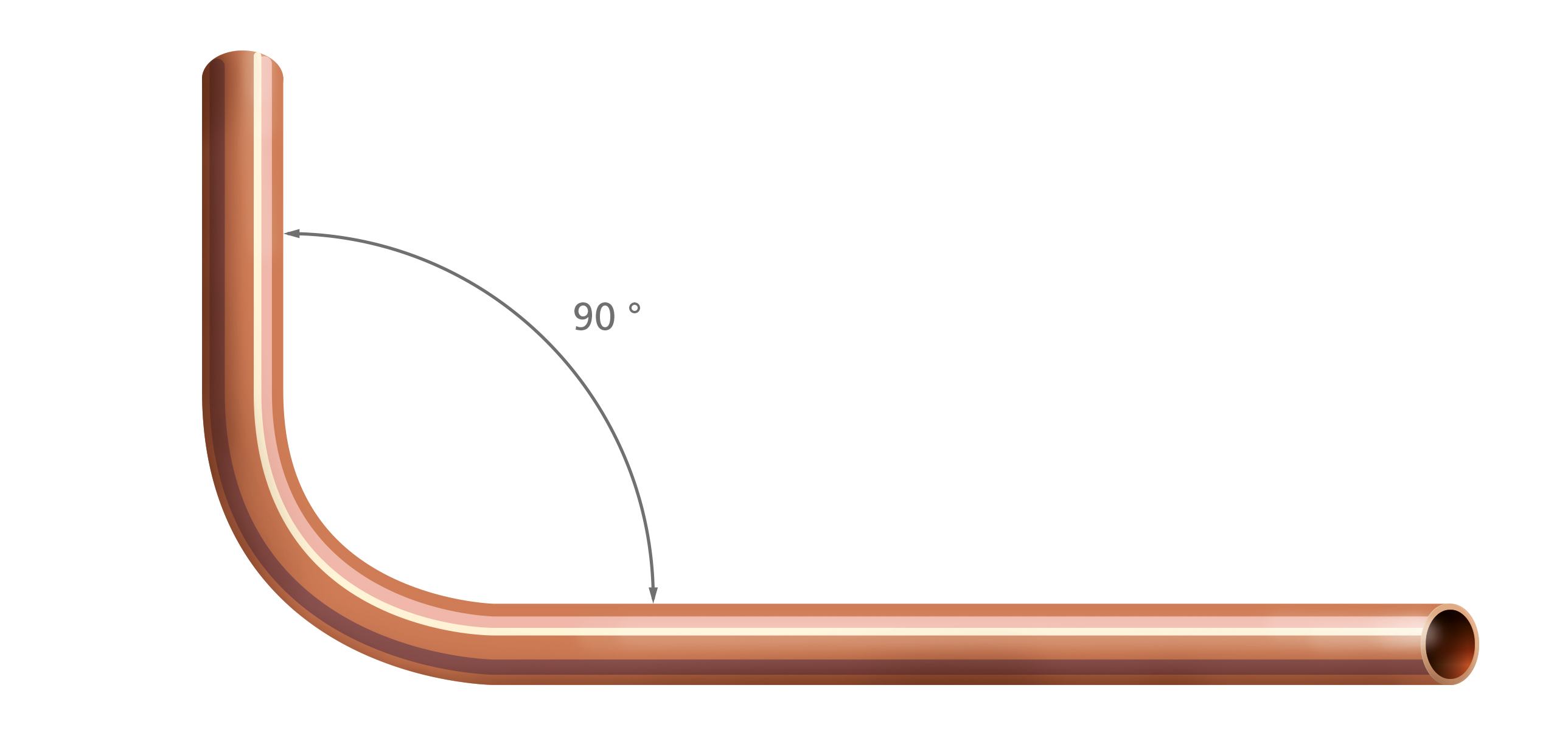

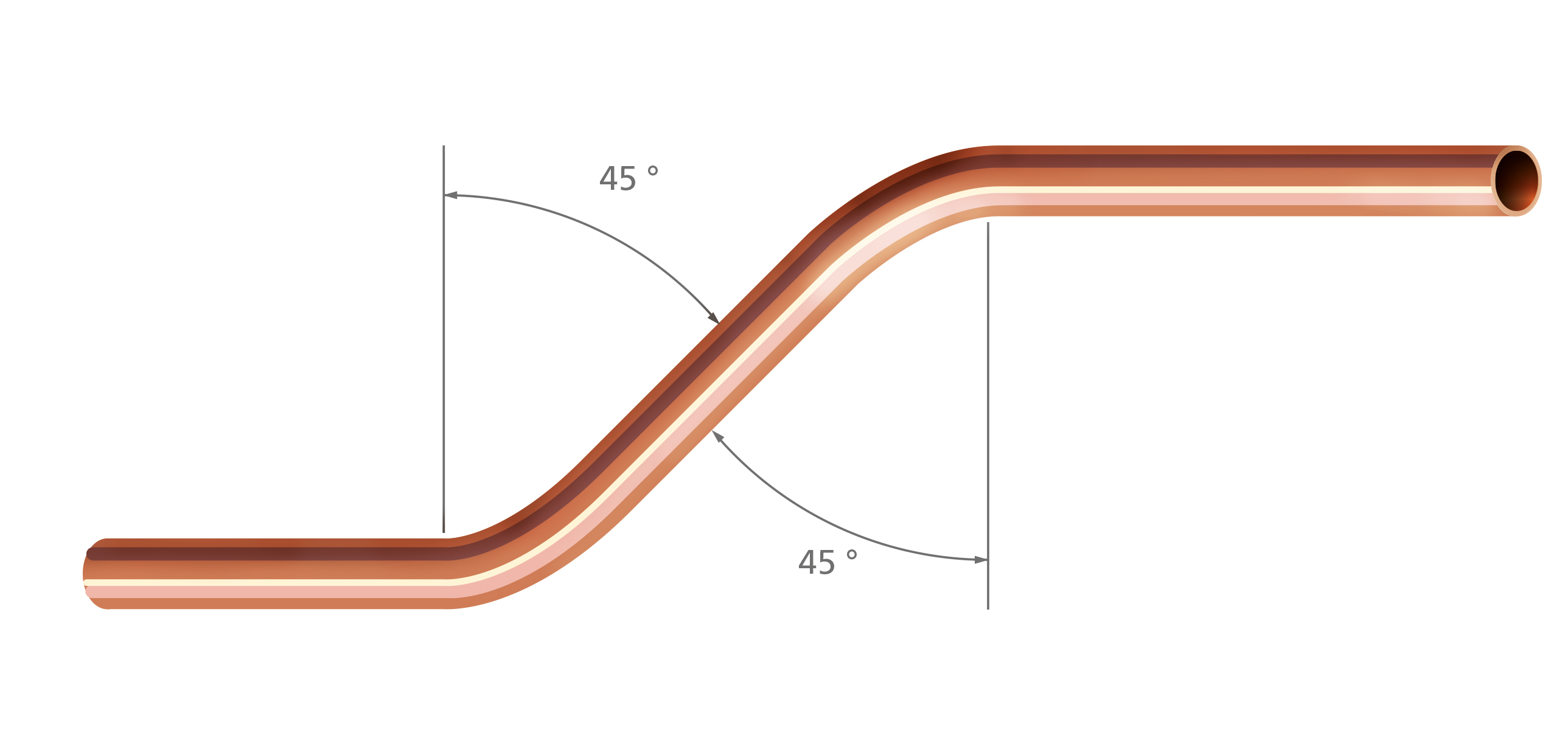

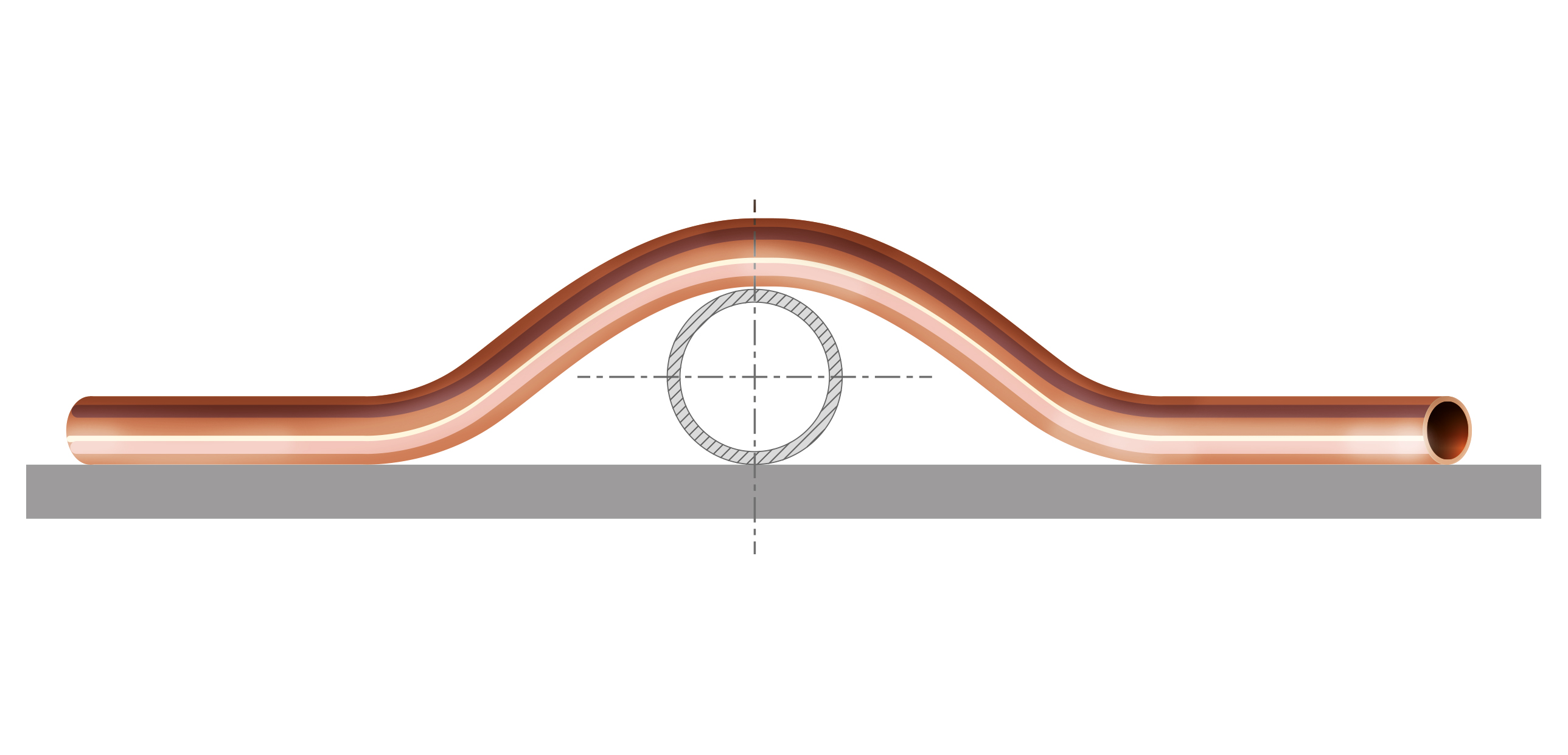

There are several bending operations: elbow bending (90 °) bayonet bending (45 ° in «S» with or without offset) or the gendarme’s hat (or crossbow) in the shape of a dome.

A- Elbow bending :

B- Bayonet bending :

B- Bayonet bending :

C- Gendarme’s hat :

In the case of annealed copper, you can directly bend the tube.

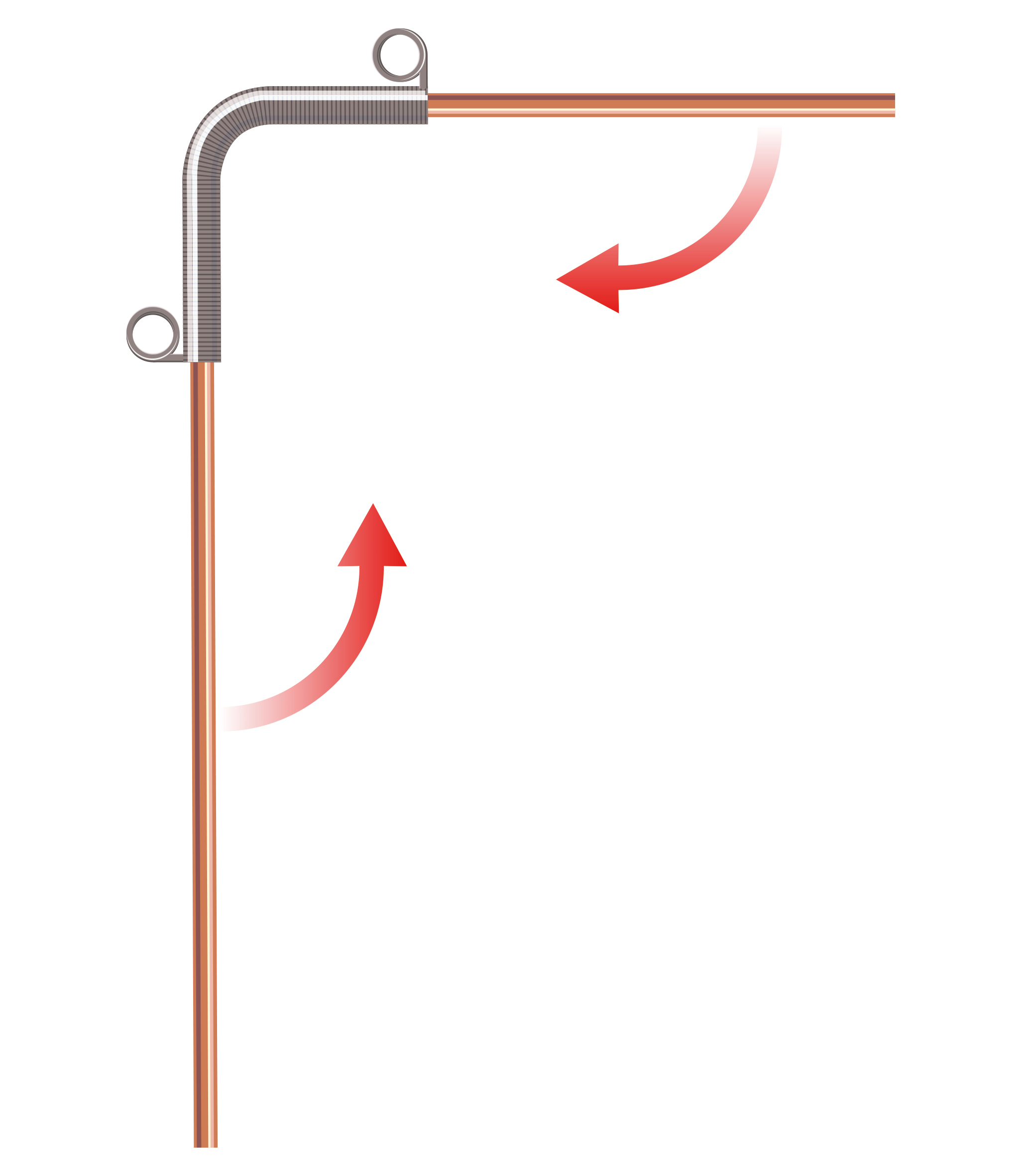

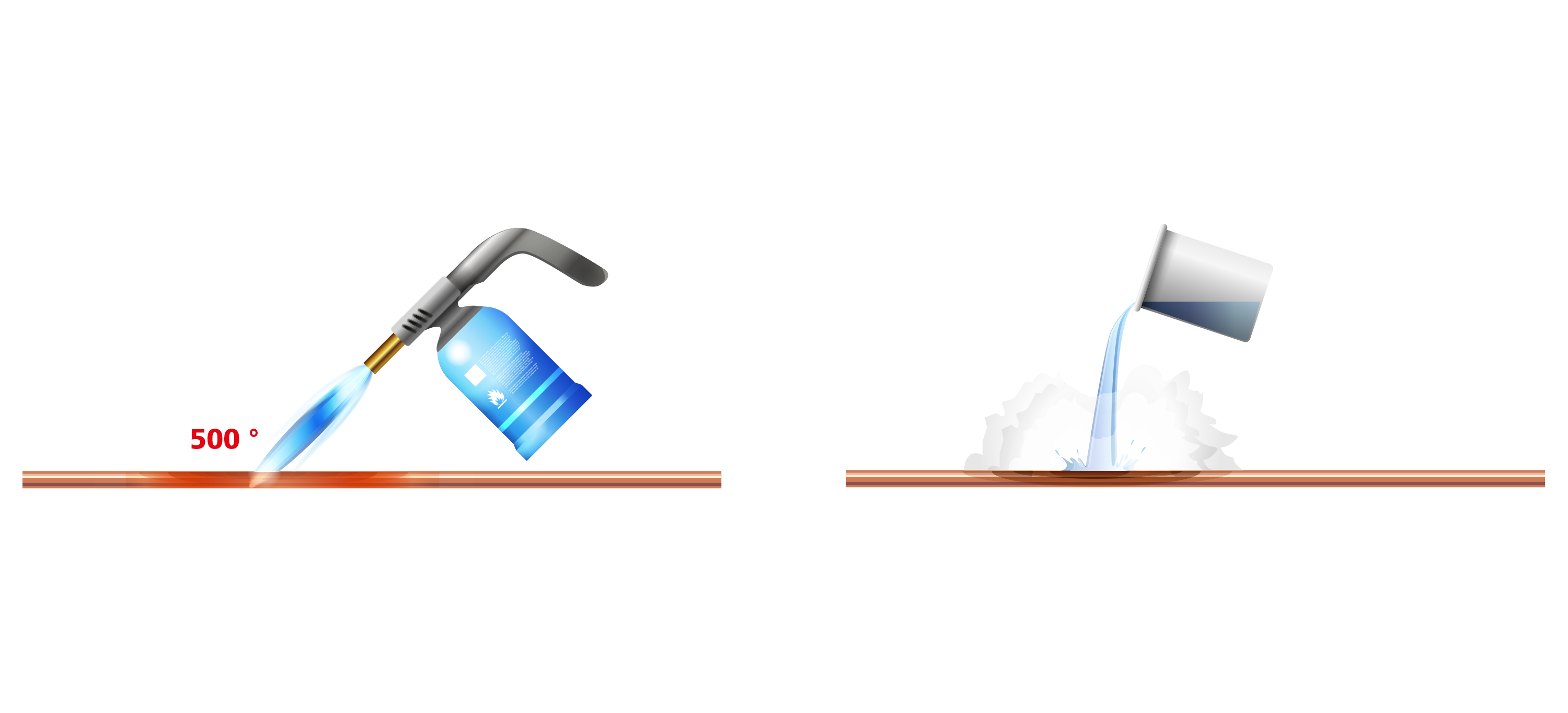

For hardened copper, you must heat it beforehand at the place of bending, with a soldering lamp or torch, up to 500 °, adding 10 cm on both sides of bending area. To bend a copper tube efficently, you can use 2 tools: the bending pliers (or bender) and the bending spring.

For the bending tool: it must match with the diameter of the tube. Heat the tube to 500 ° and cool it with water

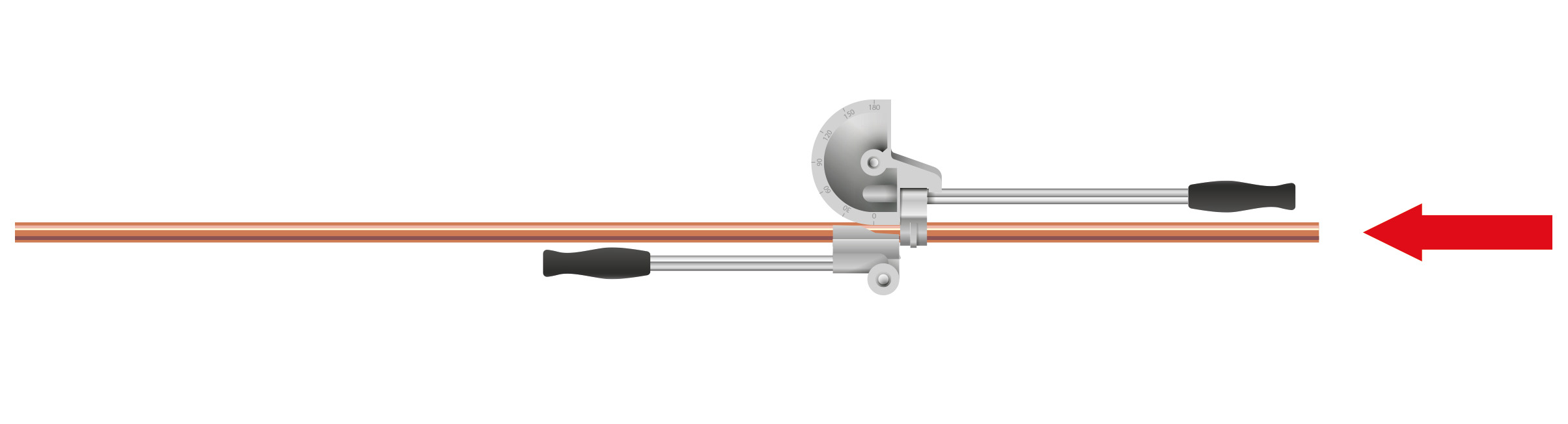

Position the tube in the throat of the latter then put it against your knee.

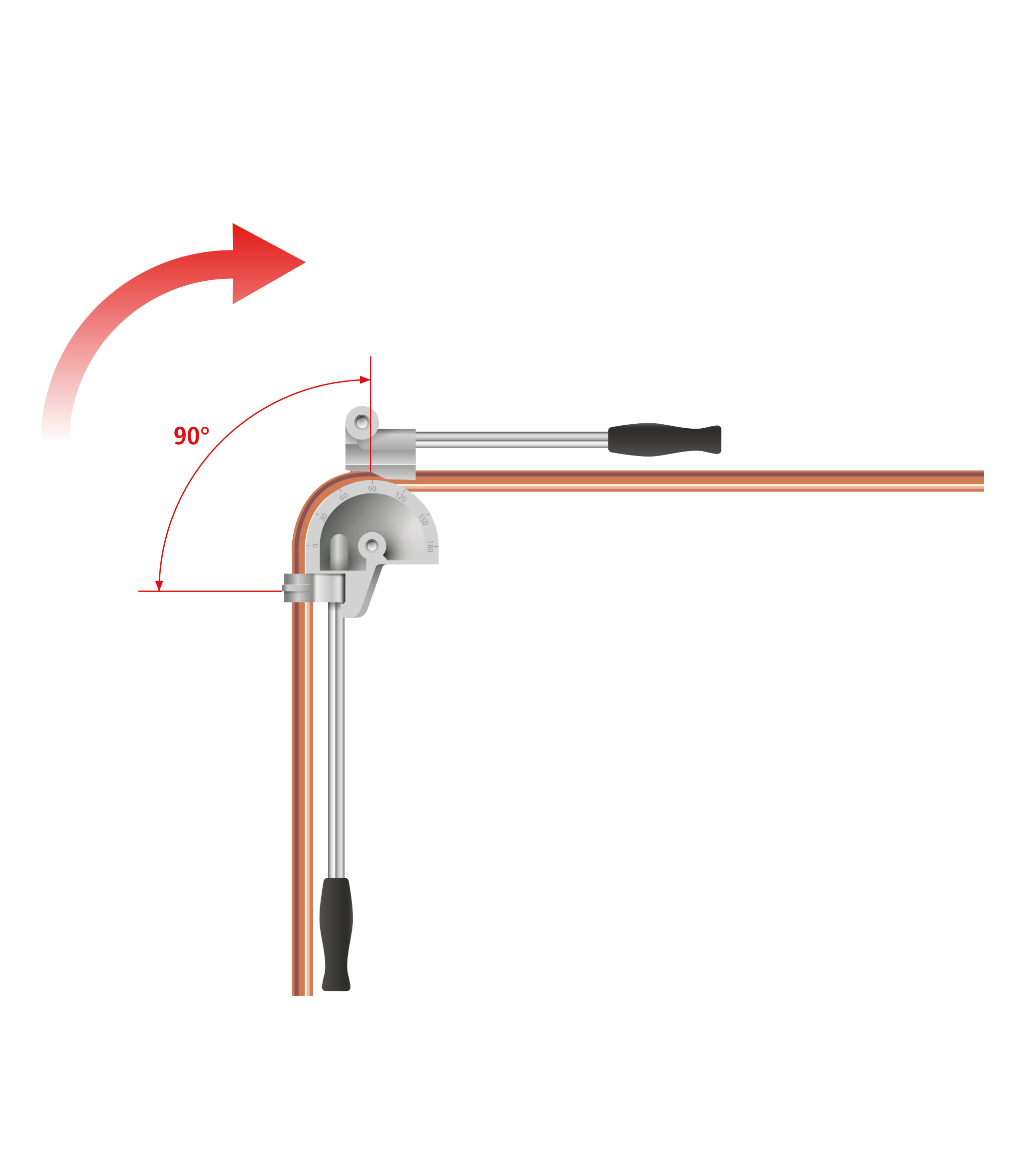

Bring both sleeves towards you to form the desired angle. You can also attach the clamp to a vise to keep your both hands free. Slowly return the guide arm handle until reaching the 0 mark on the arm, is opposite the 90 ° mark on the roller for a right angle bend (or your chosen angle mark).

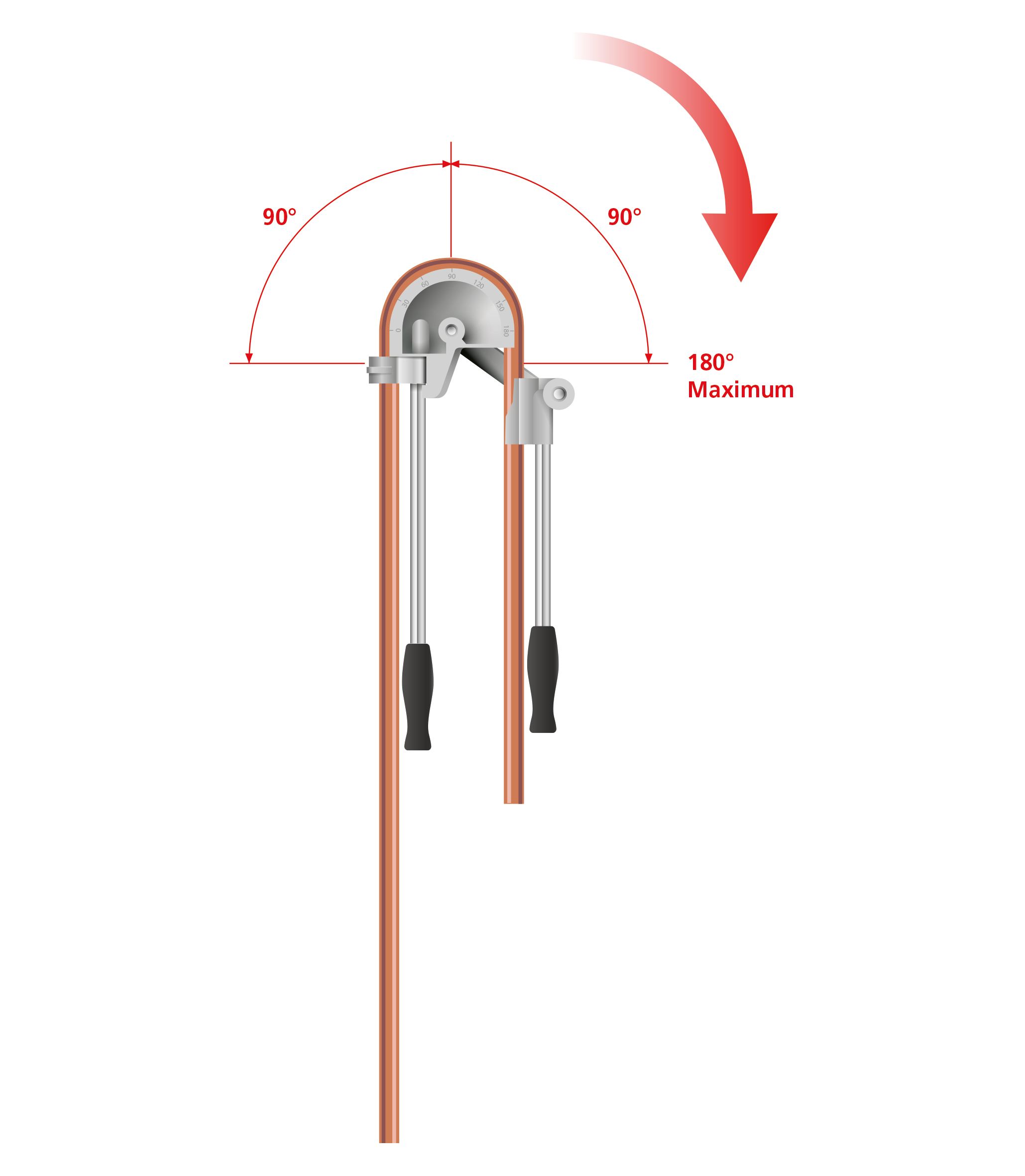

Remember to protect your hands and eyes during the operation with certified equipment. Then check if the angle is correct using a square. A tube can thus be bent up to 180 ° on the fixed jaw of the bender.

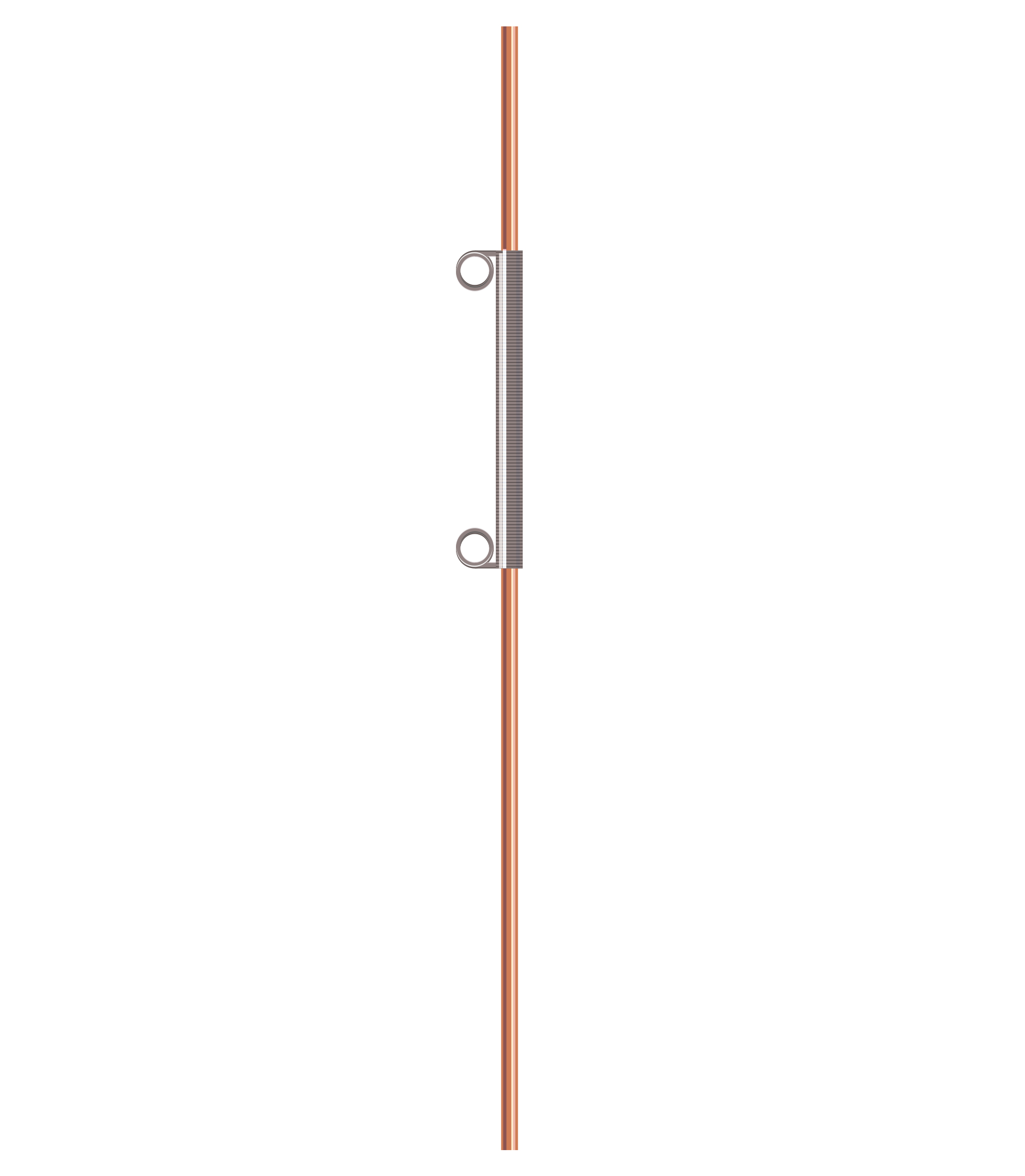

2- Bending spring

For the bending spring: Heat the tube up to 500 ° and cool it with water. You need to insert the tube into the spring where you want to bend it. The spring slides into the tube and allows it to be bent without it deforming laterally. The spring must also match exactly to the outside diameter of the tube. It is therefore defined by 2 numbers (inside diameter × outside). Example: 14 × 16 (for 16 mm tubes). Press the middle of the spring against your knee and bring its ends towards you. Some springs have two gripping rings to facilitate the catching without risk of get your hands damaged

We suggest to use a square wire spring, which is better to prevent crushing of the tube. However, the spring is a tool that is not very precise, but at a very affordable price.